Everything about the Benefits of Buying a Top Quality Pallet wrapping Device

Buying a high quality pallet wrapping device can transform product packaging operations. These makers supply enhanced Load security, making certain that products stay protected throughout transport. They likewise minimize material waste by using stretch film successfully. The benefits extend beyond these points. Exploring the full series of advantages exposes a much deeper influence on efficiency and safety within the work environment. Understanding these advantages can lead to more educated service choices. What various other variables should be considered?

Enhanced Load Stability

Enhanced Load stability is an essential advantage of buying a pallet wrapping equipment. This equipment plays a necessary duty in safeguarding tons throughout storage space and transport, minimizing the threat of shifting or toppling. By securely wrapping pallets with stretch film, the devices guarantees that private things remain in position, protecting them from damages. Boosted stability also permits safer handling, minimizing the likelihood of crashes and injuries in the workplace. With boosted Load security, business can maximize area application in shipping containers and warehouses, resulting in more effective procedures. Ultimately, the raised dependability of palletized loads cultivates self-confidence amongst consumers, suppliers, and services, enhancing total supply chain efficiency and reliability.

Lowered Product Waste

Boosted Performance and Rate

Investing in a pallet wrapping maker significantly improves efficiency and speed in product packaging operations. These equipments automate the wrapping process, permitting quicker prep work of items for delivery. By lowering the time invested on manual wrapping, companies can improve throughput and reduce bottlenecks in the process. Additionally, pallet wrapping makers offer regular results, guaranteeing that every Load is covered uniformly, which eliminates the requirement for rework. This integrity not only accelerates procedures yet additionally adds to far better stock monitoring, as products are gotten ready for circulation much more promptly. On the whole, the integration of a pallet wrapping maker brings about a significant increase in efficiency, allowing firms to fulfill customer demands much more successfully and keep an one-upmanship in the marketplace.

Enhanced Employee Safety

Lowered Handbook Handling Risks

Applying a pallet wrapping equipment substantially decreases hand-operated handling threats, improving general worker safety in industrial atmospheres. Commonly, employees by hand wrapped pallets, exposing them to various physical strain and injury threats, consisting of training and twisting. By automating this procedure, the equipment lessens the requirement for employees to participate in recurring, laborious tasks that can result in bone and joint disorders. In addition, the safe and secure and regular wrapping supplied by the maker decreases the likelihood of product changing or falling throughout transport, lowering the danger of mishaps. This not only shields the employees but also guarantees the integrity of the products being taken care of. Generally, buying a pallet wrapping maker cultivates a much safer office setting by alleviating manual taking care of dangers properly.

Improved Ergonomic Layout

The improved ergonomic layout of pallet wrapping makers substantially adds to enhanced worker security and comfort. These equipments are engineered to decrease physical strain by permitting operators to keep a neutral body position throughout procedure. pallet wrapping machine repair. Attributes such as adjustable heights and straightforward controls allow efficient handling without excessive getting to or flexing. Additionally, many versions include safety and security guards and automatic shut-off mechanisms to protect against mishaps, additionally safeguarding employees. By decreasing the physical demands of wrapping pallets, these devices reduced the risk of bone and joint injuries and fatigue, promoting a healthier work atmosphere. On the whole, buying an ergonomic pallet wrapping maker not just boosts efficiency yet likewise shows a commitment to employee wellness and safety

Affordable Packaging Option

While many businesses look for efficient methods to improve their operations, a pallet wrapping machine sticks out as an affordable packaging remedy. By automating the wrapping process, companies can greatly decrease labor expenses and minimize the moment required for packaging. This efficiency translates to higher productivity degrees, permitting businesses to allot resources to various other crucial areas. Furthermore, a pallet wrapping machine aids to minimize material waste, as it uses the appropriate amount of stretch film required to protect items without extra. This not only leads to savings on packaging materials yet additionally enhances the honesty of the products during transport. Generally, investing in a pallet wrapping maker proves to be a wise financial decision for business aiming to enhance their packaging operations.

Modification and Convenience

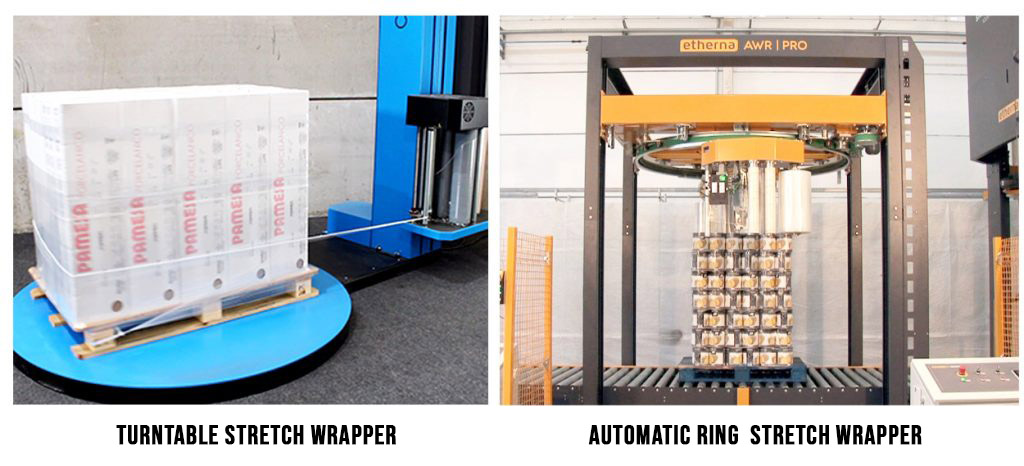

Personalization and adaptability are essential advantages of purchasing a pallet wrapping machine, permitting organizations to tailor their packaging processes to certain product needs. These devices frequently include flexible setups to suit various shapes and sizes of pallets, making certain ideal wrapping for various loads. Customers can choose the sort of wrapping tension, density, and product to improve efficiency and meet particular functional requirements. In addition, advanced models supply programmable functions, allowing quick modifications between different product packaging tasks without substantial downtime. This versatility not just streamlines the product packaging process but also improves efficiency by decreasing hand-operated adjustments. Because of this, business can efficiently respond to varying needs while preserving a high criterion of presentation and capability in their product packaging solutions.

Better Product Defense During Transportation

Making certain items get here undamaged at their location is a vital problem for companies, and purchasing a pallet wrapping device significantly boosts item defense throughout transportation. These equipments use a safe and secure layer of stretch film around pallets, producing a secure system that lessens activity during shipping. This added stability aids avoid damages from changing lots, environmental elements, and effects that can occur throughout the transport process. Furthermore, quality pallet wrapping devices can give moisture resistance, securing products from damp conditions. By properly securing and securing items, businesses can decrease the threat of loss and costly returns as a result of harmed items. Ultimately, purchasing a pallet wrapping device verifies crucial for keeping product stability and ensuring client satisfaction.

Often Asked Concerns

The length of time Does It Take to Install a Pallet wrapping Maker?

The installment time for a pallet wrapping machine usually varies from a couple of hours to a number of days, depending upon the maker's intricacy and the center's preparedness to suit the equipment.

What Upkeep Is Needed for a Pallet wrapping Equipment?

Normal upkeep for a pallet wrapping equipment includes oiling relocating components, examining and changing used parts, cleaning up the equipment, and making certain proper calibration. Scheduled inspections help prevent malfunctions and extend the devices's life-span, improving operational performance.

Can a Pallet wrapping Machine Manage Different Pallet Dimensions?

A pallet wrapping machine can commonly manage various pallet sizes, depending upon its style and requirements. pallet wrapping machine repair. Flexible setups and functions enable drivers to fit different dimensions, making certain effective and safe wrapping for diverse loads

What Is the Typical Life-span of a Pallet wrapping Device?

The ordinary life expectancy of a pallet wrapping machine normally ranges from 5 to 15 years, depending upon the model, use frequency, maintenance techniques, and operational setting, affecting overall performance and long-lasting financial investment worth.

Are There Any Certain Training Requirements for Running These Devices?

The training needs for running pallet wrapping equipments commonly consist of safety protocols, maker procedure methods, and upkeep treatments. Appropriate training assurances safe usage and makes the most of effectiveness, lowering the danger of crashes and equipment damages in the workplace.

Furthermore, pallet wrapping machines provide constant outcomes, guaranteeing that every Load is covered uniformly, which removes the requirement for rework. Investing in a pallet wrapping machine significantly boosts employee safety by decreasing the threats associated with hand-operated handling. Routine maintenance for a pallet wrapping device includes lubricating relocating components, checking and replacing worn components, cleaning up the equipment, and guaranteeing correct calibration. A pallet wrapping equipment can typically handle various pallet pallet wrapping machine repair dimensions, depending on its layout and specifications. The training requirements for operating pallet wrapping makers typically consist of security protocols, device operation strategies, and maintenance treatments.